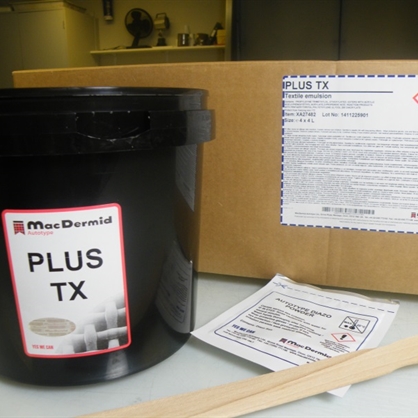

PLUS TX

PLUS TX is a truly universal textile emulsion resistant to water based, plastisol and discharge screen printing textile inks. This high quality, high solids, dark blue, dual cure Diazo sensitised emulsion can be used from very coarse (10/cm - 25/") mesh counts right up to medium fine meshes (120/cm - 305/").

Features

- The high solids emulsion gives fantastic coating quality and fast drying even on poorly prepared screens.

- A medium fast exposure coupled with wide processing latitude makes PLUS TX really easy to use.

- On press the emulsion is highly flexible to prevent cracking when over printing stitched seams and can be used with all popular textile inks including, water based, plastisol and discharge inks.

- After printing the emulsion can be decoated using Autostrip.

- Diazo dual cure sensitiser - for extreme toughness

- 44% solids - fast drying and good bridging on coarse meshes

- Dark blue - good contrast

- Water, plastisol and discharge ink resistant - a universal textile emulsion

- Highly flexible - will not crack

- Decoatable - screens can be re-used

Applications

- PLUS TX is formulated for all textile printing applications that use either water based inks, plastisol inks or discharge inks.

Additional Information

WORKING INSTRUCTIONS & SAFE HANDLING

Sensitising of Emulsion

Note: New ‘direct addition’ of Diazo

Handle PLUS TX under yellow fluorescent tubes or low wattage Tungsten light. PLUS TX is supplied as a two pack kit comprising the emulsion and powder sensitiser in a sachet.

- Prior to sensitising read the Safety Data Sheet. Mix the two components as follows:

- Cut the powder diazo sachet open using a pair of scissors (DO NOT OPEN WITH TEETH).

- Add the powder diazo sensitiser DIRECTLY to the emulsion.(DO NOT DISSOLVE THE SENSITISER IN WATER OR ADD ADDITIONAL WATER TO THE EMULSION).

- Stir thoroughly for approximately 2-3 minutes to ensure emulsion is sensitised throughout. Allow the emulsion to de-gas for 15 minutes before use.

Mesh Preparation

Unused polyester Autoprep Gel and Universal Mesh Prep or Auto Degreaser Concentrate

Used polyester Universal Mesh Prep or Auto Degreaser Concentrate

For more information on mesh preparation, follow this link to: How to Guide - Mesh preparation for PLUS emulsions

Coating & Drying

Stand the screen on edge, angled away from the operator and, using a good quality coating trough, proceed as follows:

- Apply 2 coats to the print of the screen.

- Apply 2 coats to squeegee side.

- The screen should be dried horizontally, squeegee side up and stored under dark or yellow light conditions. Dry the screen at a maximum temperature of 30°C (86°F).

- Additional coatings may be applied to the underside of the screen with intermediate drying.

For more information on coating, follow this link to: How to Guide - Coating PLUS emulsions

Exposure

CORRECT EXPOSURE IS ESSENTIAL FOR OPTIMUM STENCIL PERFORMANCE. UNDEREXPOSURE WILL GIVE A WEAK STENCIL AND REDUCE RESISTANCE.

Remove dust from the surface of the stencil and tape positive in position. Place entire screen in a suitable vacuum frame and expose. We recommend use of the Autotype Exposure Calculator for test exposures to ascertain correct timing. Exposure times below should be used as a guide:-

Exposure Time (minutes)*

* Based on 2+2 coating on 90/cm (230/inch) dyed monofilament polyester mesh.

For more information on coating, follow this link to: How to Guide - Exposing PLUS emulsions

Washout & Drying

Wash out the screen from both sides with a strong spray of water. Continue the washout until all parts of the image appear clean and sharp. Blot off surplus moisture with newsprint or a leather and dry at a maximum temperature of 30°C (86°F).

Spot out blemishes with sensitised emulsion.

Stencil Removal

Remove ink from the screen, with Autosolve screen cleaner. Apply Autostrip to both sides of the screen. Leave standing for 5 minutes. The stencil can then be removed with a strong water jet or high pressure stripper. If a stain or ghost image still remains, use Autokleen Plus.

For more information on decoating, follow this link to: How to Guide - Decoating PLUS emulsions

Product Literature

Applications

How to Guides

No related guides