受控膜版Capillex CP/CX毛细水菲林操作指南

Synopsis...

Capillex CX - Industrial Printing

When printing high specification industrial inks, especially functional inks such as conductive or resistive, it is critical that the print is as close a reproduction to the original film positive as possible. As the shape, width and height of the printed track will have a huge impact on the way that track functions

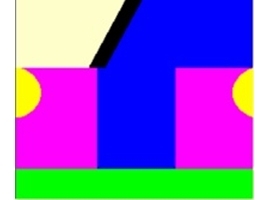

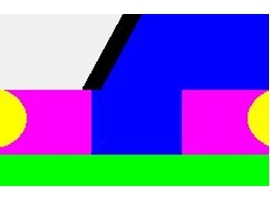

For example, the print to the left is what I want to print: But the print on the right is what I actually get: You can clearly see the second print has small areas missing from the top edge, a fault that is known as 'negative sawtoothing'. This Silver conductive track would not function as well as the track above as the resistance will be higher.

At the other end of the scale is a printing faulty known as 'positive sawtoothing'. This is a common screen printing fault which is caused by too rough a stencil surface on the print side (high Rz) of the screen which allows the ink to spread out underneath the stencil edge. If you were to overlay the film positive back on top of this print in register you would see that the print is bigger than the image (positive). Whereas with the 'negative sawtoothed' image this is smaller than image on the film.

The industry accepted cure for a positive sawtoothed image is to use a stencil with a flatter surface (low Rz) on the print side. However, when using conventional stencil systems this can lead you to create a high stencil thickness in order to get this flat stencil surface. And in turn it is this high stencil thickness (Emulsion Over Mesh or EOM) that can lead to negative sawtoothing.

The only difference between these two prints was the stencil thickness (EOM). Both these images were printed with a silver ink through a 90.40/cm (230.40/inch) mesh. The good print on the left hand side had a stencil profile of 4µ whereas the image on the right hand side had a stencil profile of 13µ.

The traditional way to overcome negative sawtoothing is to increase the squeegee pressure to force the ink down the long channel created by the thick stencil, but by increasing the pressure this will cause the image to distort and the stencil to break down quickly. This would be a major problem when printing tight register multilayer images such as biosensors.

No matter how flat the stencil is, a thick stencil (> 10µ EOM) is harder to print than a thin, flat stencil. Quite simply, a thick stencil requires considerably more squeegee pressure to force the ink down into contact with the substrate.

On the other hand, a thin, flat stencil requires far less pressure to bring the ink into contact with the substrate and as a result gives a more controllable print and with control comes productivity. It is this combination of a thin flat stencil for industrial printing that is combined in Capillex CX.

Capillex CX is based on the revolutionary new Controlled Profile stencil technology as used in Capillex CP to provide a thin, flat stencil that is both easy to use and very tough. Typically Capillex CX will produce an EOM of only 4µ on a mesh range of 62/cm - 120/cm (150/inch - 305/inch) combined with a low Rz.

The benefits that the low EOM and Rz of Capillex CX bring to the high quality Industrial printer are:

- Minimises ink deposit to produce a 'square profile' print

- Improves photographic resolution of fine highlights

- Reduced squeegee pressure

- Improves ink transfer for fine lines

- Reduces image distortion

- Reduces stencil wear

Capillex CX is extremely easy to use from small to large format, especially when used with the new Caplicator programme from MacDermid Autotype.

Capillex CX is particularly suited for applications where ink deposit and print definition will have a direct influence on the performance. Such as conductive or resistive inks.

Conclusion

Capillex CX will give you greater control of the process. With this control comes predictability, so you know what you will get before you start printing.

This control means less wastage, faster set up times and greater productivity.

For more information on Capillex CX follow this link.