Download Print Friendly Version: French Spanish Czech English Hungarian Chinese Dutch German Swedish Polish Italian Russian

How to Guide - Haze Removal

Synopsis...

Using dirty, stained screens can lead to low quality prints and expensive stencil breakdown. This How to Guide provides essential advice on how to choose the best haze removal system to remove screen stains and ghost images.

The importance of haze removal:

Most ghost images are made up of microscopic residues on the mesh left over from the previous job. These residues not only prevent the stencil from adhering properly, they can even affect the way in which the ink flows through the mesh to cause a latent ‘ghost’ image in the print. Therefore, it is very important that these residues are removed from the mesh during the cleaning process.

Prevention is better than cure:

Before going into detail about haze removal, it is worth stating that a few simple steps can be taken to reduce, or even eliminate, the formation of screen haze and stains. Exposing screens correctly, cleaning them as soon as possible after printing and using the right Screen Wash, can minimise and even eliminate the need for an additional haze removal process, saving time and money.

Identifying the type of stain

Typically ghost images come from one or more of the following: fused Acetate ‘(locked-in screens’) or Diazo from the stencil, ink that has dried-in, ink staining of the mesh fibres, or even mechanical abrasion of the mesh itself. Knowing the root cause of the stain will then help you choose the ideal haze remover to clean it.

Top tip: As a simple guide if the stain is the same as the print, then it has come from the ink and if it is a negative of the print, it has come from the stencil.

Stencil stains

There are two types of stencil stains:

Diazo stains - Diazo sensitisers are chemical dyes and are therefore, very effective at dyeing Polyester mesh. The yellow/brown stain left by Diazo can easily be removed by using a low caustic haze remover, such as Autokleen Plus. If the Diazo stain is very noticeable, it is usually an indication that the stencil has been under-exposed.

Fused Acetate stains - These are easily recognisable as a lightly coloured, translucent residue left on the screen where the stencil was. These stains can be removed using a low caustic haze remover such as Autokleen Plus activated with Autosolve Industrial AF Screen Wash.

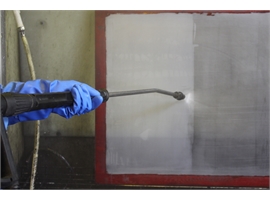

Top tip: It is much easier to remove stencil stains immediately after decoating the stencil whilst the screens are still wet. If they are allowed to dry out fully, then the acetate hardens and becomes more difficult to remove. Use the High Pressure Gun on both sides of the screen for the best effect.

Ink stains

There are five main types of ink stains:

Dried-in ink - If the ink has been allowed to dry in the mesh after printing it is very easy to see. Most inks can be re-dissolved in a powerful cleaning solvent, such as Autosolve, which makes removing them straightforward. Stubborn stains may require the use of a more aggressive solvent and low caustic blend, such as Quick Clean.

Top tip: Applying a ‘stain preventer gel’ to the screen immediately after printing can make cleaning much easier.

Hardened ink - Two-pack catalysed inks are notoriously difficult to remove, as they are formulated to be highly resistant once they have hardened. You will need to use an aggressive very high caustic and solvent haze remover, such as Autohaze, to have any chance of breaking these down. The longer the catalysed inks have been allowed to react the harder they will be to remove.

UV cured inks - Screens that have been used for printing UV curing inks should not be left in a white light area as they will quickly harden and become much more difficult to remove. They will require a high caustic and solvent haze remover, such as Autohaze Extra to remove them. Therefore, it is best to store these screens under yellow safelight (go to macdermid.com/autotype How to Guide – Coating PLUS Emulsions for advice on safelights).

Ink staining of the mesh fibres - Some inks will actually dye polyester thread during printing. If this does happen the stain can only be removed with a very strong caustic haze remover, such as Autohaze. Although this type of stain does not reduce the mesh opening diameter it can cause problems during the exposure of subsequent stencils due to differential UV light absorption.

Mechanical abrasion of the mesh fibres - Although not strictly mesh staining, these ghost images are quite rare and are typically caused by printing very long runs with an abrasive ink. For example, ceramic inks contain a glass frit which will micro-abrade the mesh as it flows through the image. If the is screen is then reused to print a sensitive ink, such as a transparent, then the previous image may appear in the print as a ghost. Haze removers will have no effect on this type of stain and it is best to discard the mesh after printing.

How to remove common ink stains

Most inks can be removed completely without mesh staining if they are cleaned immediately after printing with the right cleaning solvents.

The Autosolve range of screen cleaning solvents are specially formulated by MacDermid Autotype to combine cleaning power with low evaporation so they work efficiently and stay longer in the screen.

Use the Autotype Brush to apply Autosolve directly onto the screen. This ergonomically designed brush has soft chemically resistant fibres that help hold the solvent without dripping and will not damage even the finest mesh fibres.

Autosolve screen wash solvents can be rinsed away with water to leave a clean screen ready to be degreased for the next job.

How to use Autosolve screen cleaning solvents

Brush Autosolve thoroughly into both sides of the screen until all the ink is dissolved and then immediately rinse with cold water before using a High Pressure Gun.

How to remove difficult ink stains

Some inks simply do stain the mesh fibres worse than others, so when you need a bit more cleaning power than Autosolve alone, then Quick Clean is the answer. This powerful solvent blend also has a low caustic content to increase its cleaning efficiency. Quick Clean is especially good on UV ink stains.

How to use Quick Clean

Use the Autotype Brush to work Quick Clean into both sides of the screen until all the stain is covered, wait five minutes and then rinse with cold water before using a High Pressure Gun.

How to remove combination of stencil and ink stains – for regular use

Autokleen Plus is the perfect answer, this low caustic, general purpose haze remover is ideal for everyday use.

How to use Autokleen Plus

Simply apply this thickened liquid to both sides of the dry screen using either the Autotype Brush, or even an old coating trough.

For optimum results with Autokleen Plus, it is best to allow the screen to dry overnight and then activate it in the morning by brushing on Autosolve Industrial AF withthe Autotype Brush. Rinse well with cold water and then finish off with a High Pressure Gun. This method is ideal if you have a number of screens that need to be de-hazed at one time.

For quicker haze removal, the Autokleen Plus coated screen can be dried with a cold air fan and then ‘activated’ with Autosolve Industrial AF immediately before rinsing off and then blasting with the gun. For very light stains try applying Autosolve Industrial AF immediately after applying Autokleen Plus and then rinse off.

How to remove stubborn ink and stencil stains – for occasional use

Autohaze Extra is a highly effective screen haze remover that quickly removes most ghost images and stubborn screen stains. The blend of strong caustic and powerful solvents is highly effective against most common screen stains and screens are ‘like new again’ in just 10 minutes. Supplied as a thickened liquid, Autohaze Extra is easier to brush onto the screen than a conventional paste as it will not run as some non-thickened haze removers do.For really stubborn stains, Autohaze Extra can be activated with Autosolve Industrial AF screen cleaning solvent immediately before rinsing.

Autohaze Extra removes stains left by the following inks: Plastisol, water based textile, discharge, UV, vinyl, electronics, ceramics and many more. Autohaze Extra also quickly removes stencil and Diazo stains in under 10 minutes.

How to use Autohaze Extra

Use the Autotype Brush or an old coating trough to apply Autohaze Extra to both sides of the dry mesh.

Leave for up to 10 minutes and then rinse off with a low pressure water spray. Blast the screen with a High Pressure Gun

How to remove very difficult ink and stencil stains – for occasional use

Autohaze is a very strong caustic and solvent paste that is designed for occasional use on very stubborn stains. When nothing else will touch it that is the time to try Autohaze.

How to use Autohaze

Autohaze is most effective when it is applied to both sides of a wet mesh using the Autotype Brush. Leave to stand for a maximum of 8 minutes before rinsing off with a cold water spray, then use a High Pressure Gun.

Safe handling:

Haze removers are powerful chemicals and must be handled carefully. Always read the Safety Data Sheet before use and wear PPE when handling them. It is very important to always rinse off any haze remover with a low pressure spray before using the High Pressure Gun, otherwise you will atomise the chemical and expose the operator to this mist. Did you know, when atomised caustic lands on screens that have already been cleaned they will produce pinholes the next time they are used?

All caustics react with aluminium, so take care when applying the low viscosity haze removers to aluminium frames and they should not be left in an aluminium scoop coater overnight.

Top tip: A High Pressure Gun should be classed as an essential piece of screen making equipment as it will save you time, money and materials in cleaning screens. A good quality industrial High Pressure Gun producing at least 75 BAR will clean screens quicker and outlast the cheaper alternatives.

The Autotype Haze Remover range

Download Print Friendly Version French Spanish Czech English Hungarian Chinese Dutch German Swedish Polish Italian Russian