操作及安全建议- Windotex

Synopsis...

1. PRODUCT DESCRIPTION AND APPLICATION

Windotex™ lacquers are UV curable, 100% solids screen printable window lacquers. Windotex™ is designed for use with Autotex® to produce clear windows. This affords the manufacturer a simple and cost effective way of producing high quality windows without the need for die cutting or selective texturing.

Product Range:

Windotex™ Gloss: >80% gloss level

Windotex™ Antiglare: 50-75% gloss level

2. AUTOTEX RECEPTIVITY, REACTIVE SURFACE TECHNOLOGY

Windotex™ is designed to be screen printed onto Autotex to produce windows for LCD and LED displays.

The Autotex surface is extremely inert and chemically resistant. It is normally impossible to achieve good adhesion onto this type of surface. In order to overcome this challenge MacDermid Autotype developed REACTIVE SURFACE TECHNOLOGY for Autotex.

The Autotex® surface is modified using unique chemistry. The surface provides highly reactive key sites onto which Windotex™ products can bind. The strong chemical bonds formed between Autotex® and cured Windotex™ provides 100% permanent adhesion.

2.1 Stability of Reactive Sites

The Autotex® key sites are so highly reactive that exposure to air and even low levels of light cause a slow loss of Windotex™ receptivity. The normal packaging of the material prevents this deterioration.

When removed from the packaging and exposed to a normal print room atmosphere for up to 48 hours subsequent windowing will normally give a good adhesion result. However, if left for longer than this prior to printing, the Autotex® surface will become completely inert.

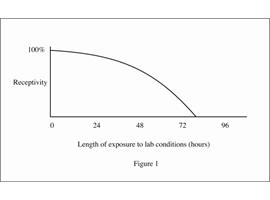

The time taken for this to occur will be dependant on ambient conditions. All Windotex™ receptivity will then be lost. Figure 1 shows how the receptivity changes with time. This data is based upon laboratory results, the actual rate of deterioration may vary according to the storage conditions used. The user must therefore perform tests to establish the useful life of the product under particular operating conditions.

2.2 Printing Recommendations

In order to achieve the best adhesion results Windotex™ should be applied within 48 hours, preferably within 24 hours, of removing Autotex® from its packaging. When printing multi-coloured graphic inks; the Windotex™ should be applied as early in the process as possible, preferably as the first or second printing operation. If it is necessary to store Autotex® for longer periods between operations before the application of Windotex™ the sheets should be stacked and wrapped. In this way shelf life is considerably extended.

Please note that for the unique textured surface of Autotex® Softouch™ window printing must be performed within 24 hours of the film being exposed to the atmosphere.

ONCE WINDOTEX HAS BEEN PRINTED AND CURED ONTO AUTOTEX THE ADHESIVE BOND IS PERMANENT AND WILL NOT DETERIORATE UNDER NORMAL OPERATING CONDITIONS.

3. WORKING INSTRUCTIONS

3.1 General

Whenever a window is required Windotex™ is screen printed onto the Autotex® texture and then UV cured. Select the appropriate Windotex™ product for the required finish:

Windotex™ Gloss: full gloss, high transparency

Windotex™ Antiglare: slightly matt, antiglare

These products may be intermixed to achieve intermediate finishes if required. The precise gloss result will depend on the printing and curing conditions in use. Under controlled processing conditions reproducible results are achieved.

The working areas should be out of direct sunlight, away from windows and shielded from other sources of UV light such as exposure units. Artificial light should not affect the product.

THE WORKROOM SHOULD BE KEPT CLEAN AND DUST FREE.

Any contamination will cause surface imperfections in the windows. Windotex™ should not be left on the mesh when not printing. Particular care should be taken to ensure the substrate is cleaned before printing. MacDermid Autotype’s antistatic dusters are suitable for this purpose.

To avoid contaminating unused lacquer, never return used Windotex™ to the pot.

Roll of Autotex Steel and Autotex Brushed

The grain in Autotex Steel and Brushed runs in the machine direction

3.2 Printing

Best results have been achieved when the Windotex™ has been thoroughly stirred for 2 minutes before use with a clean spatula. Note that sharp metal spatulas can scrape particles of plastic from the inner surface of the pot. Care should be taken to avoid this source of contamination. Air bubbles formed during stirring will not lead to air in the finished window. The recommended print thickness is 15±2 microns for Gloss and 13±2 microns for Antiglare above the textured surface of Autotex®.

3.3 Curing

The windows should be cured immediately after printing to prevent dust contamination. However, if a clean room is available, a flow out period up to 30 seconds produces windows with greater clarity. Prior to or during curing the print should not be placed on an uneven and/or hot surface as this can cause cosmetic defects at the points of contact. Use a card or metal plate to support the print if necessary. Total UV dose of 500-700 mJ/cm2 is recommended.

Windotex™ Gloss and Antiglare contain different photo initiator systems. This means they may need slightly different curing conditions to obtain optimum hardness.

High intensity outputs produce harder and more scratch resistant windows compared to low intensity outputs.

3.4 Shelf Life

Windotex™ Gloss and Antiglare have a 12 month shelf life. The filler in Windotex™ Antiglare will settle out over time. It is therefore important to always stir the pot thoroughly before printing.

4. GLOSS LEVELS (Windotex Antiglare Only)

Different curing units will give different gloss levels. A unit with active substrate cooling will give a higher gloss level than a unit with no direct substrate cooling.

A high powered unit (e.g. 120 watts/cm) is likely to give a higher gloss level than a unit with lower power.

Optimum curing conditions are highly dependant upon the curing unit. Experimentation will be required.

5. HEALTH & SAFETY

ENSURE ALL USERS READ THIS INFORMATION

These products are solely intended for use as an industrial printing lacquer for producing windows on Autotex® textured polyester film. MacDermid Autotype accepts no liability whatsoever if used for any other purpose.

5.1 Hazards in Use:

THIS PRODUCT DOES NOT CONTAIN N-VINYL PYRROLIDONE (NVP)

a) Eyes and Skin:

Hazards associated with this product derive from the presence of acrylate monomer. This monomer is irritating to eyes, skin and by inhalation, and may cause sensitisation by skin contact.

No harmful effects should result if the products are used according to the instructions for the stated applications. Operatives must wear protective clothing providing complete ski polyethylene or nitrile rubber gloves and goggles, and work in an area with good mechanically driven ventilation.

Air flow must be exhausted not re-circulated. Care must be taken when using cleaning solvents as they may cause the deterioration of the protective clothing/gloves allowing the product to penetrate.

b) Ingestion:

The material is non toxic, but ingestion may cause internal irritation and associated symptoms, therefore do not smoke, eat or drink when using this product.

c) Inhalation

The solution is non-volatile under normal circumstances. However it must not be exposed to naked flames, hot surfaces or reactive chemicals as these may cause decomposition, producing irritating and toxic fumes, which must not be inhaled.

Detailed toxicological information is not available on all components. Care in handling and adherence to the above procedures is therefore essential.

KEEP OUT OF REACH OF CHILDREN

5.2 Storage

The lacquers should be stored in their original containers in a cool place away from direct heat and sunlight. Do not keep or use in an area with reactive chemicals. Shelf life is 12 months.

5.3 Disposal

Dispose of product as chemical or solvent waste via an authorised chemical disposal agency. Do not contaminate the drainage system.

5.4 Spillage

Small amounts may be removed with wipes or if necessary a solvent-based screens wash and then incinerated. Large spillages should be absorbed in an inert material such as sand or sawdust, and transferred to a safe site for chemical disposal by a recognised authority.

Do not allow contamination of the drainage system. Spilled material will not dry in the absence of UV light. When dealing with spillage ensure that personnel are adequately protected.

5.5 Fire Precautions

These products have a flash point >100oC and are not considered flammable. However, because thermal decomposition can occur above this temperature, involvement in a fire may produce large volumes of toxic decomposition products (CO, NOX). Breathing apparatus should be used. CO2 or dry powder extinguishers should be used in case of fire.

6. FIRST AID

a) Ingestion: Do not induce vomiting. Wash out mouth. Seek medical attention.

b) Inhalation: Remove to fresh air. Rest and keep warm. Drink water. Check breathing, administer oxygen if necessary. Seek medical attention.

c) Eyes: Irrigate with water for 15 minutes. Seek medical attention.

d) Skin: Wash thoroughly with soap and water. Avoid exposure of affected areas to direct sunlight for 24 hours.

7. PACKAGING

Windotex™ is sold in volumes of 1 litre in plastic containers.