Download Print Friendly Version: Dutch Hungarian Italian Russian Polish Chinese German Czech Swedish French Spanish English

感光乳胶曝光操作指南

Synopsis...

Choosing the Right Light Source

As a general rule, the minimum distance between the exposure lamp and the vacuum frame should be equal to the diagonal of the area to be exposed. This will ensure fairly even illumination over the exposure area.

Light Sources

Most modern light sources are based on gas discharge, each type having specific advantages and disadvantages.

Image courtesy of Natgraph Ltd

Spectral Output of Light Sources

In general terms a light source with a spectral output in the region of 340-440 nM (nanometers) is suitable for exposing photostencil materials. Some light sources have a continuous output, whereas others have a discontinuous or line emission. Modern light sources such as metal halide lamps have a line output and it is important that these emissions coincide with that portion of the sensitivity curve of the photostencil materials, giving the best results in terms of tanning and image contrast i.e. diazo bulbs or photopolymer bulbs.

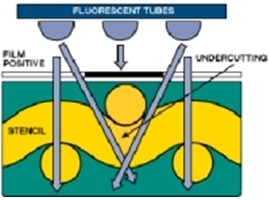

(A) UV Fluorescent Tubes

These are used in some printing down frames and have the advantage of pure UV without producing heat. However because their output is very low they have to be used in banks very near to the photostencil with consequent problems of light undercutting. If considering UV fluorescent tubes as a source, ensure that their output is suitable, ie between approximately 340-440 nM, blue tubes used in sun beds are the best choice.

(B) High pressure Mercury vapour lamp

The HPR lamp works by vaporising and ionising mercury which normally takes 2-3 minutes from switch on. Once the lamp has been switched off the mercury condenses before it can be vaporised again.The HPR lamp has a relatively low output and a line spectrum with high peaks in the ultra-violet and blue regions. When exposing large areas a number of lamps must be used with consequent undercutting problems and areas of uneven exposure.The HPR lamp normally has a life of about 1000-1500 hours, after which the UV output tends to fall off. A practical light source for small stencils and the hobbyist.

(C) Metal Halide lamp

Metal Halide lamps are now the industry standard and are recommended by MacDermid Autotype as the most practical light source to use. They consists of a quartz envelope containing mercury through which a current passes, vaporising the mercury. Like the HPR lamp, it has a discontinuous line spectrum and requires a restart time, although instant start models are now common. With the addition of metal halides it is possible to adjust the spectral output within the UV and blue parts of the spectrum.The lamp has an average life of around 1,000 hours. It is ideally suited to the exposure of photostencils - clean, efficient and fast because of its relatively high power and high UV output. Different doping materials are used to produce 'Diazo', 'Photopolymer' or 'Universal' bulbs depending on your requirements.

Light intergrators

Timing an exposure is not the most accurate way of ensuring that the stencil has received the correct amount of light. A light integrator will compensate for these variations, since the exposure is controlled by the amount of light falling on a photocell placed on a vacuum frame. An additional advantage of the light integrator is that, regardless of lamp position, once an optimum exposure level has been found, no further adjustments are required.

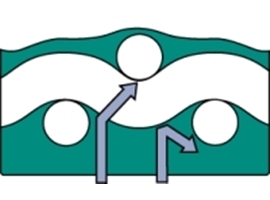

Mesh effects on exposure

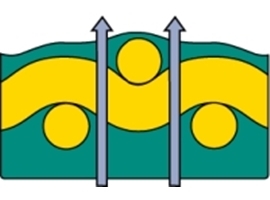

When exposing Capillex, treat the photostencil and mesh as a complete entity because of the influence of the mesh on light scatter. This affects both resolution, definition and exposure level.The diagram below shows the light scatter caused by white mesh. Scatter increases with the increase in mesh count and exposure time. As this can cause considerable loss of resolution and definition it is recommended that dyed meshes are used, especially when reproducing fine detail.

Dyed meshes absorb the UV light, thus minimising light scatter hence exposure times have to be increased by 50-150% over the times used for white mesh.

Vacuum Frames

The contact between the positive and the photostencil should be as perfect as possible, as inadequate contact results in light undercutting. Particles must not be trapped between the two surfaces and if using large vacuum frames fitted with flexible rubber blankets allow sufficient time for all the air to be exhausted. In some cases the blanket can become stretched, especially after processing many direct stencils. It may be necessary to use a piece of flexible tubing near or around the positive and connected to the blanket vacuum inlet to insure proper air evacuation by channelling the air.

Light Source Geometry

The photographic properties of photostencils which are influenced by exposure are resolution and definition. Resolution is taken to be the limit of reproduction achievable i.e how fine a line can you resolve. Definition is the reproductive quality, for example, the straightness of edges of print.

Light spread

Photostencils are designed to obtain a specific resolution, but once they are over-exposed, light spread in the emulsion will reduce this resolution ; ie open areas will start to close in. This is influenced by mesh colour, film positive contact and angles at which the UV enters the stencil.

Light source Geometry

If the light rays passing through the positive and photostencil material emulsion are not parallel, changes will occur in the image reproduced in the photostencil. This is often referred to as light undercutting. From a practical point of view, poor light geometry effects do not present a problem when processing general work, ie lettering down to about 6 point and halftones of 65 lines (25 cm) or coarser. It is only when trying to accurately reproduce very fine line halftones or images, that attention must be paid to light geometry.

Factors influencing light geometry

(a) Size of the light source. The larger a source, the greater becomes the angle of light rays travelling from its edges and therefore the degree of undercutting.

(b) Position of the light source. The nearer a light source is to the vacuum frame the greater is its effective size. Conversely if the lamp is moved further away, so its effective size is reduced. It is good practice to increase lamp distance when exposing very fine detail work to reduce the effect of light undercutting if at all practical, (do not forget that the exposure time will have to be adjusted if an integrator is not fitted).

Positive quality and the absorption of the film base

The film positive determines the image quality of the stencil.

For optimum results use single-layer positives with the emulsion side in contact with the photostencil during exposure.This ensures that light undercutting will be restricted and that the stencil will be uniformly exposed. It will be noted that a normal 100 micron (0.004") polyester film base absorbs a high proportion of the UV light. So when using stripped up positives with two or more layers of film plus adhesive tape, considerable variations in stencil exposure will result. Exposure times have to be adjusted accordingly for the best overall result. Multi-layer positives increase the amount of spotting-out time so careful consideration should be given to the real cost differences between single and multi-layer positives.

Download Print Friendly Version Dutch Hungarian Italian Russian Polish Chinese German Czech Swedish French Spanish English