印刷建议 - Autoflex EB

Synopsis...

1. GRAPHIC INKS

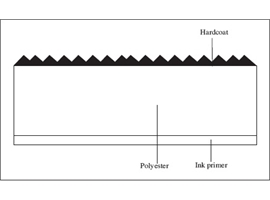

Autoflex EB is based upon biaxially orientated polyester film. Therefore, it has excellent solvent resistant characteristics. Screen printing inks may therefore be used without risk of the ink solvents penetrating the film.

Other commonly used substrates such as polycarbonate and PVC, can be seriously affected by ink solvent penetration. This leads to cosmetic deterioration and reduced flex life.

The ink receptivity of the second surface of MacDermid Autotype products has been greatly enhanced by the application of a specifically formulated primer coating.

The printing surface is therefore not polyester film and the printer is not restricted to the use of inks formulated for polyester substrates.

1.1 Ink Selection

1.1.1 Successful Ink Selection

Suitable inks are to be found in most manufacturers’ ranges. A selection of the inks tested in our laboratories and found to give good results under our test conditions are presented below.1

Pre-production testing of specific inks must always be carried out under the user’s processing conditions. Within an ink range different colours may vary in performance.

Autoflex EB has an ink adhesion primer on the second surface. This primer confers excellent adhesion to a wide range of solvent based graphic inks. The primer is not recommended for use with UV cured graphics inks or a combination of solvent and UV graphic inks because the adhesion performance will be inconsistent. A special UV primer is available, see Autoflex (7 Series) datasheet.

1.1.2 High Opacity Metallic and Transparent Inks

It has been clearly established that use of high opacity inks from an otherwise recommended range can lead to adhesion problems, due to the high pigment:binder ratio, which means that there is less resin to adhere the ink to the substrate. We therefore recommend that under no circumstances should high opacity inks be used, either on their own or in a colour blend. If necessary, two layers of the standard white may be printed in order to achieve the required opacity: this should not cause an adhesion problem.

Decorative metallic colours may also contain higher pigment levels than standard and will therefore show poorer adhesion. These colours are also not recommended for use on our primers.

Transparent colours within a range may perform differently to solid colours and so should be thoroughly tested separately.

|

Manufacturer |

Ink Range |

|

ARGON |

Thermoplus, Carbogloss |

|

NAZDAR |

GV |

|

PRINTCOLOR |

Easy Switch 346 |

|

PROLL |

Thermojet + 5020 adhesion improver |

|

COATES |

Touchkey HG |

|

SEIKO |

PAL/GAP, Advance GAT series |

|

SERICOL |

Sertiec TH, Polyplast PY |

|

TOYO |

SS66-000 |

|

DEBUIT |

24800 |

|

MARABU |

Marastar SR, Maraswitch MSW |

|

VISPROX |

Multiplast 300 |

|

JUJO |

9000 series, 9100 series |

|

Teikoku |

EG, IPX series |

|

Nazdar |

8800/3400 series |

1 For test method see Test Method Manual

1.2 Printing and Drying

Inks printed onto polyester substrates dry more slowly than identical inks printed onto solvent- sensitive substrates such as polycarbonate. This is because evaporation cannot occur by the migration of solvent through the impermeable polyester film. The more rapid drying of inks on polycarbonate is achieved only at the expense of solvent attack on the film. This commonly leads to premature flex fatigue in use.

Special care must be taken therefore when printing Autoflex to ensure that each ink layer is thoroughly dried before application of the next.

An ink which is touch dry may still contain a considerable quantity of retained solvent. Once laminated into a switch or panel this solvent cannot escape and adhesion problems may result. Retained solvent is readily detected by its strong odour. Over time, this will migrate to the interface between the ink and substrate, causing the ink to delaminate - visible as silvery patches in the overlay. (This effect may not be apparent for several weeks, or even months.) The trapped solvent will also soften the ink, causing its adhesion to the substrate to worsen. For these reasons, thorough drying of each ink layer is essential.